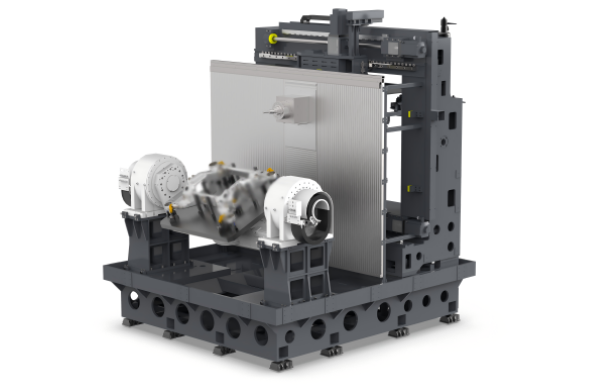

Rail transit profile processing center: key equipment to improve rail transit construction efficiency

August 14, 2024

The rail transit profile processing center is an important equipment in modern rail transit construction. It not only plays a vital role in the construction of rail transit systems, but also greatly improves processing efficiency and precision. With the help of the rail transit profile processing center, we can produce high-quality rail transit profiles more quickly, thereby promoting the development of the entire rail transit industry.

1. Basic functions of rail transit profile processing center

The rail transit profile processing center is mainly used to process various profiles in rail transit systems, such as rails, support frames and bridge components. These profiles play a supporting and connecting role in construction, and their processing accuracy is crucial. Therefore, rail transit profile processing equipment needs to combine advanced CNC technology and automated processing processes to achieve precise cutting, drilling, milling and tapping of profiles.

1. High-precision processing

The rail transit profile processing center is equipped with a high-precision CNC system that can process with micron-level precision. For example, it can cut and drill with almost no errors, ensuring that the processed profiles perfectly meet the design requirements. This high-precision processing not only reduces the time for subsequent adjustments, but also ensures the stability and safety of the rail transit system.

2. Automated processing

Modern rail transit profile processing centers have a high degree of automation. The automatic loading, processing and unloading system enables the equipment to complete the entire processing process without human intervention. In this way, not only the production efficiency is greatly improved, but also the errors that may be caused by manual intervention are reduced.

3. Flexible processing capabilities

The rail transit profile processing center can process profiles of various specifications and materials. Whether it is steel, aluminum alloy or other metal materials, the equipment can be processed accordingly according to specific needs. This flexibility enables the rail transit profile processing center to play a role in various rail transit projects, from urban light rail to high-speed rail, which cannot be separated from its support.

2. Extensive industry application

The rail transit profile processing center not only plays an important role in rail transit construction, but is also widely used in other related fields. For example, in bridge construction, building structures and heavy machinery manufacturing, this equipment can effectively improve the processing efficiency and quality of profiles.

1. Urban rail transit

In the urban rail transit system, the rail transit profile processing center can produce high-precision tracks, bridges and supporting structures to ensure the smooth operation of urban rail transit. The construction of urban light rail and subway systems cannot be separated from the support of such equipment.

2. High-speed railway

High-speed railways have extremely high requirements for tracks and supporting structures, and the high-precision and high-efficiency processing capabilities of the rail transit profile processing center just meet this demand. It can ensure the stability and safety of the high-speed railway system.

3. Bridge construction

Profile processing in bridge construction is also inseparable from the rail transit profile processing center. These equipment can process precise bridge support structures to ensure the stability and safety of bridges.

3. Future development trends

With the continuous advancement of science and technology, rail transit profile processing centers are also developing continuously. In the future, with the introduction of intelligent and digital technologies, rail transit profile processing centers will be more intelligent and automated. They will be able to better adapt to complex and changing engineering needs and improve processing efficiency and precision.

1. Intelligent control

The future rail transit profile processing center will integrate more intelligent control technologies, such as artificial intelligence and big data analysis. This will enable the equipment to monitor the processing process in real time and automatically adjust the processing parameters to cope with various changes.

2. Higher processing accuracy

With the advancement of technology, the processing accuracy of rail transit profile processing centers will be further improved. Future equipment will be able to complete processing within a smaller tolerance range and meet more stringent engineering requirements.

3. Environmental protection and energy saving

The future rail transit profile processing center will pay more attention to environmental protection and energy saving. New equipment will adopt more efficient energy utilization technology to reduce the impact on the environment during the production process.

Conclusion

The role of rail transit profile processing center in rail transit construction cannot be underestimated. It provides a solid guarantee for the stable operation of the rail transit system through high-precision and high-efficiency processing. With the continuous advancement of technology, these equipment will become more intelligent and precise, promoting the development of the entire rail transit industry.

If you have more interest or needs in rail transit profile processing centers, please consult us, we will provide you with detailed information and professional advice. Please contact us now to learn more about our rail transit profile processing center!